PVC PIPE TECHNICAL SPECIFICATION

PVC Pipes produced by Polyvinyl Chloride raw material and used for many projects. The PVC pipes firstly used for drinking water networks, however nowadays used for many projects in the worlwide. The PVC Pipes can be apply for most of the projects which is used Polyethylene piping projects and resistant to bad weather condition. PVC Pipes doesn’t leak because uses with rubber ring to avoid leakage. PVC Pipes are safely preffered by the engineers on the underground.

PVC pipes preffered due to easly installation specialty. PVC Pipes have three kind of joining method of the installation that one of the most using is by self-muff PVC Pipes, the second one of the connecting method of PVC Pipes is by solvent cement PVC pipe that pipes are joining by tangit glue. And the last one of the joining PVC pipes preffered by coupler and rubber Q-ring connection type.

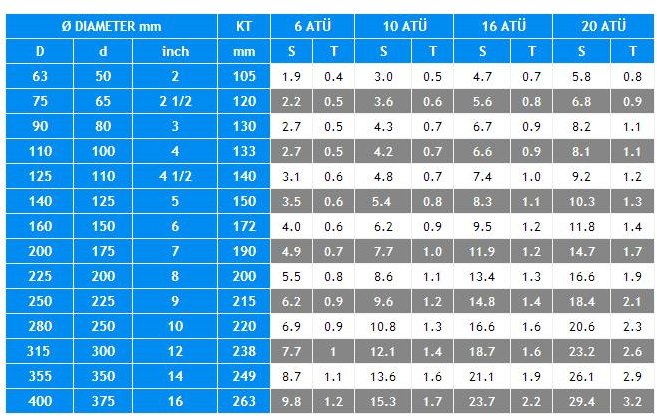

PVC PIPE TESTING & TECNICAL PARAMETERS TABLE

PVC pipes manufacturing according to standard of EN ISO 1452-2, DIN 8061 DIN 8062 for hte projects required. PVC clean water networks it’s produced by pressure numbers and PVC Sewage projects produced by SN number. PVC Pipe produced as below size;

U- PVC Pipe Sizes;

| U-PVC PIPES DIAMETERS TABLE | OD (mm) |

| 50 mm PN 10 – PN 16 U-PVC Pipes | 50 |

| 75 mm PN 10 – PN 16 U-PVC Pipes | 75 |

| 90 mm PN 10 – PN 16 U-PVC Pipes | 90 |

| 110 mm PN 10 – PN 16 U-PVC Pipes | 110 |

| 140 mm PN 10 – PN 16 U-PVC Pipes | 140 |

| 180 mm PN 10 – PN 16 U-PVC Pipes | 180 |

| 200 mm PN 10 – PN 16 U-PVC Pipes | 200 |

| 225 mm PN 10 – PN 16 U-PVC Pipes | 225 |

| 250 mm PN 10 – PN 16 U-PVC Pipes | 250 |

| 280 mm PN 10 – PN 16 U-PVC Pipes | 300 |

| 315 mm PN 10 – PN 16 U-PVC Pipes | 400 |

| 400 mm PN 10 – PN 16 U-PVC Pipes | 500 |

| 500 mm PN 10 – PN 16 U-PVC Pipes | 600 |

| 600PN 10 – PN 16 U-PVC Pipes | 700 |

U- PVC Pipe Technical Table;

PVC BORU TEKNİK ÖZELLİKLERİ

PVC Borular Polivinil Klorid hammaddesinden üretilerek, birçok altyapı projesinde güvenle tercih edilirler. Önceleri sadece içme suyu projelerinde kullanılan PVC Borular, artık dünyaçapında hertürlü projelerde sıklıkla tercih edilirler.

PVC Borular dünya standartlarına uygun olarak üretilirler. Dünyanın birçok yerinde kullanılan standartlardan olan EN ISO 1452-2, DIN 8061 DIN 8062 standartlarına uygun olarak üretilen PVC Borular istenen uygulamalarda kullanılır.

PVC Boru Çapları için Tablo aşağıdaki gibidir;

| PVC BORU ÇAPLARI | OD (mm) |

| 50 mm PN 10 – PN 16 PVC Boru | 50 |

| 75 mm PN 10 – PN 16 PVC Boru | 75 |

| 90 mm PN 10 – PN 16 PVC Boru | 90 |

| 110 mm PN 10 – PN 16 PVC Boru | 110 |

| 140 mm PN 10 – PN 16 PVC Boru | 140 |

| 180 mm PN 10 – PN 16 PVC Boru | 180 |

| 200 mm PN 10 – PN 16 PVC Boru | 200 |

| 225 mm PN 10 – PN 16 PVC Boru | 225 |

| 250 mm PN 10 – PN 16 PVC Boru | 250 |

| 280 mm PN 10 – PN 16 PVC Boru | 280 |

| 315 mm PN 10 – PN 16 PVC Boru | 315 |

| 400 mm PN 10 – PN 16 PVC Boru | 400 |

| 500 mm PN 10 – PN 16 PVC Boru | 500 |

| 600 mm PN 10 – PN 16 PVC Boru | 600 |

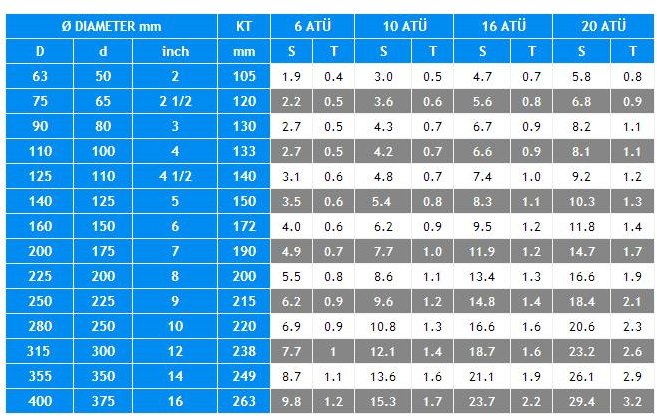

PVC Boru Teknik Tablosu

[:es]

[:es]

CARACTERISTICAS TECNICAS DEL TUBO PVC

Caracteristicas de Tubos de PVC producidos por la materia prima de cloruro de polivinilo y usados para muchos proyectos. Los tubos de PVC en primer lugar utilizados para redes de agua potable, sin embargo utilizan hoy en día para muchos proyectos en el nivel mundial. Las Tuberías de PVC se pueden aplicar para la mayoría de los proyectos que se utiliza proyectos de tuberías de polietileno y resistentes a las malas condiciones climáticas. Tuberías de PVC no se escapan porque usos con anillo de goma para evitar fugas. Tuberías de PVC se preffered de forma segura por los ingenieros en el metro.

Tubos de PVC preferidos debido a easly especialidad instalación. Tuberías de PVC tienen tres tipos de método de unión de la instalación de que uno de los más utilizando es mediante tubos de PVC auto-manguito, el segundo uno de los métodos de conexión de las tuberías de PVC es por solvente tubería de PVC de cemento que las tuberías están uniendo con pegamento Tangit. Y la última de las tuberías de PVC de unión preferidos por acoplador y caucho anillo Q tipo de conexión.

PVC TUBO DE PRUEBA Y TÉCNICA parámetros de la tabla

Tubos de PVC de fabricación de acuerdo con la norma EN ISO 1452-2, DIN 8061 DIN 8062 para proyectos hte requeridos. Redes de agua limpia de PVC es producido por los números de la presión y proyectos de PVC de aguas residuales producidas por número SN. Tubería de PVC produce como continuación de tamaño;

Tuberias de PVC DIMENSIONES;

| U-PVC TUBOS DIÁMETROS TABLA | OD (mm) |

| 50 mm PN 10 – PN 16 Tuberias de PVC | 50 |

| 75 mm PN 10 – PN 16 Tubos de PVC | 75 |

| 90 mm PN 10 – PN 16 Tubos de PVC | 90 |

| 110 mm PN 10 – PN 16 Tuberias de PVC | 110 |

| 140 mm PN 10 – PN 16 Tubos de PVC | 140 |

| 180 mm PN 10 – PN 16 Tubos de PVC | 180 |

| 200 mm PN 10 – PN 16 Tubos de PVC | 200 |

| 225 mm PN 10 – PN 16 Tubos de PVC | 225 |

| 250 mm PN 10 – PN 16 Tubos de PVC | 250 |

| 280 mm PN 10 – PN 16 Tubos de PVC | 300 |

| 315 mm PN 10 – PN 16 Tubos de PVC | 400 |

| 400 mm PN 10 – PN 16 Tubos de PVC | 500 |

| 500 mm PN 10 – PN 16 Tubos de PVC | 600 |

| 600PN 10 – PN 16 Tubos de PVC | 700 |

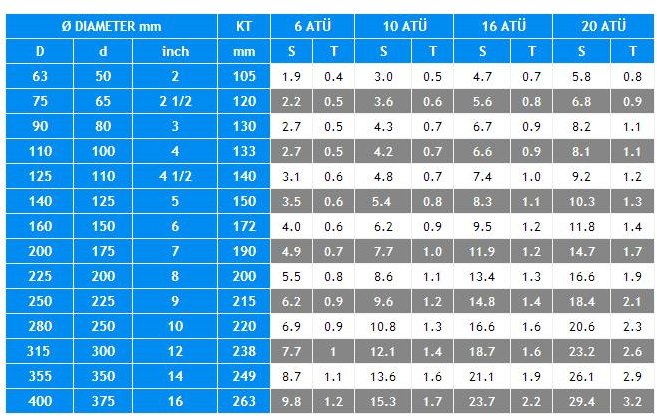

PVC Tubería Mesa Técnica;